Manage & Track Your SCBA

The SCBA Module tracks the full history for each piece of SCBA gear from purchase to retirement. Document any type of event - inspections, hydrostat tests, air fills, flow tests, repairs, contaminant exposures, and more. View expiration dates and maintenance costs for better forecasting and to justify when things need to be replaced.

KEEP TRACK OF ALL YOUR GEAR.

Find what you're looking for

Organize every cylinder, pack, mask, RIT pack, and cascade across your entire department - and search for it quickly by type, serial number, expiration date, and more.

You send it, we'll load it

Just provide a list of your gear - in whatever format you have - and we'll organize and upload it all for you. If you're starting from scratch, we'll provide gear templates and best practices that other departments utilize.

Evolves with your department

Admin can edit, add, and retire gear in the system in minutes, so your inventory is always up-to-date.

LOG INSPECTIONS ANYTIME, ANYWHERE.

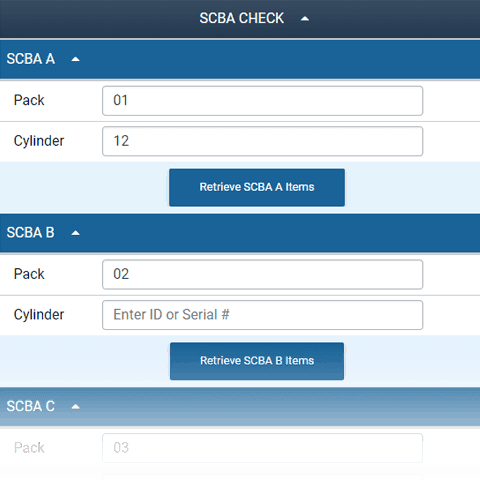

Inspect vehicle-assigned SCBA

SCBA checks are integrated with the truck checks for gear that is assigned to your vehicles. That way you can track which packs and bottles are riding on which truck at any given time.

Ensure that your gear is keeping you safe

Crew members can post alerts on any gear that doesn't pass inspection - and automatically email the personnel responsible for taking action. The malfunctioning gear can be pulled from service, repaired, and returned to service when fixed. Everything is logged in the gear's history, so there's a full account of each inspection, alert, and repair from day one.

Switch gear assignments seamlessly

Pack and cylinder locations are automatically saved to their positions on the trucks. When the gear changes, just type in the ID of the new gear and it'll save there until the next time it's changed.

Robust reports

Easily run reports for expiration dates, hydrostatic testing, air fill logs, inspection history, alerts, repairs, and more - then export them quickly to PDF or Excel.

Inspections customized for you

We load checks adapted from NFPA 1852, but you can customize them to your specs. Inspections can be scheduled and logged when they're due (i.e. with truck checks) or performed as-needed (i.e. post-call).

FULL HISTORY, FROM PURCHASE TO RETIREMENT.

Every inspection, alert, assignment change, and status change is automatically documented in each gear's detail history. You can see everything that happened on any piece of gear (i.e. "Show me the full history of Pack 17 since purchase") or you can search in bulk (i.e. "Show me every Routine Inspection logged last year"). You can always export this information into a PDF or Excel file, if needed.

"We use PSTrax to not only complete our monthly inspections, but to track annual gear inspections, SCBA inspections, flow testing, hydro testing, gear inventory, return to service checklists and to send alerts for issues that come up. PSTrax has given us that one place to do all of these things and the members can do it all on their phones." Eric Forand, Deputy ChiefBristol Fire Department (VT)

All your checksin one place.

Vehicles

Manage all your vehicle checks and inventories.

Stations

Manage all your station and building checks.

Supplies

Track all your EMS and station consumables.

Assets

Manage all your high-dollar assets.

SCBA

Manage all your SCBA equipment.

PPE

Manage all your PPE gear.

Controlled Substances

Track all of your controlled substance vials.

FAQ's

Yes, Fire and EMS Station Tracking Software is customizable to meet the specific needs of each organization.

The components to be checked include the facepiece, regulator, cylinder, harness, pressure gauge, and alarm systems. Each component plays a vital role in maintaining the functionality and integrity of the SCBA unit.

Typically, checks should be performed before each use, as well as at regular intervals, such as monthly or quarterly, to ensure ongoing reliability. Check manufacturers instructions to be sure.

The steps may include inspecting the facepiece for cracks or worn-out parts, checking the regulator for proper functionality, ensuring the cylinder is fully charged and securely attached, examining the harness for damage or loose straps, verifying the accuracy of pressure gauges, and testing the alarm systems for audibility and responsiveness.

If firefighters identify a problem during an SCBA check, it is crucial to follow established protocols. They should immediately report the issue to their supervisor or maintenance personnel and refrain from using the faulty equipment.

Yes, training is essential for firefighters to perform SCBA checks effectively.